Creative and innovative engineering design helping businesses to grow.

Our extensive knowledge and experience over many years in the industry provides an outsourced design service from the technical to the creative for our customers’ products, with support over the product life cycle. We work with entrepreneurs, business owners and key decision makers to provide design solutions for businesses across multiple industries.

Have a look below to find out more about us and the services we provide:

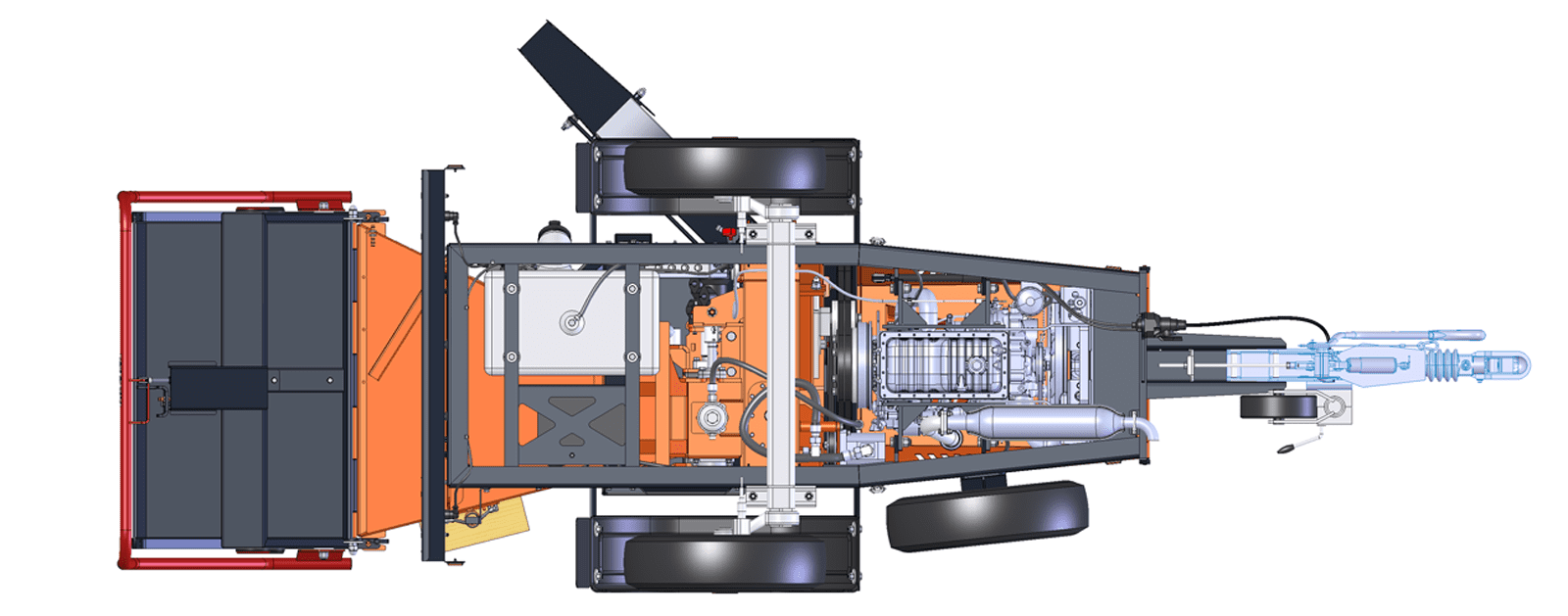

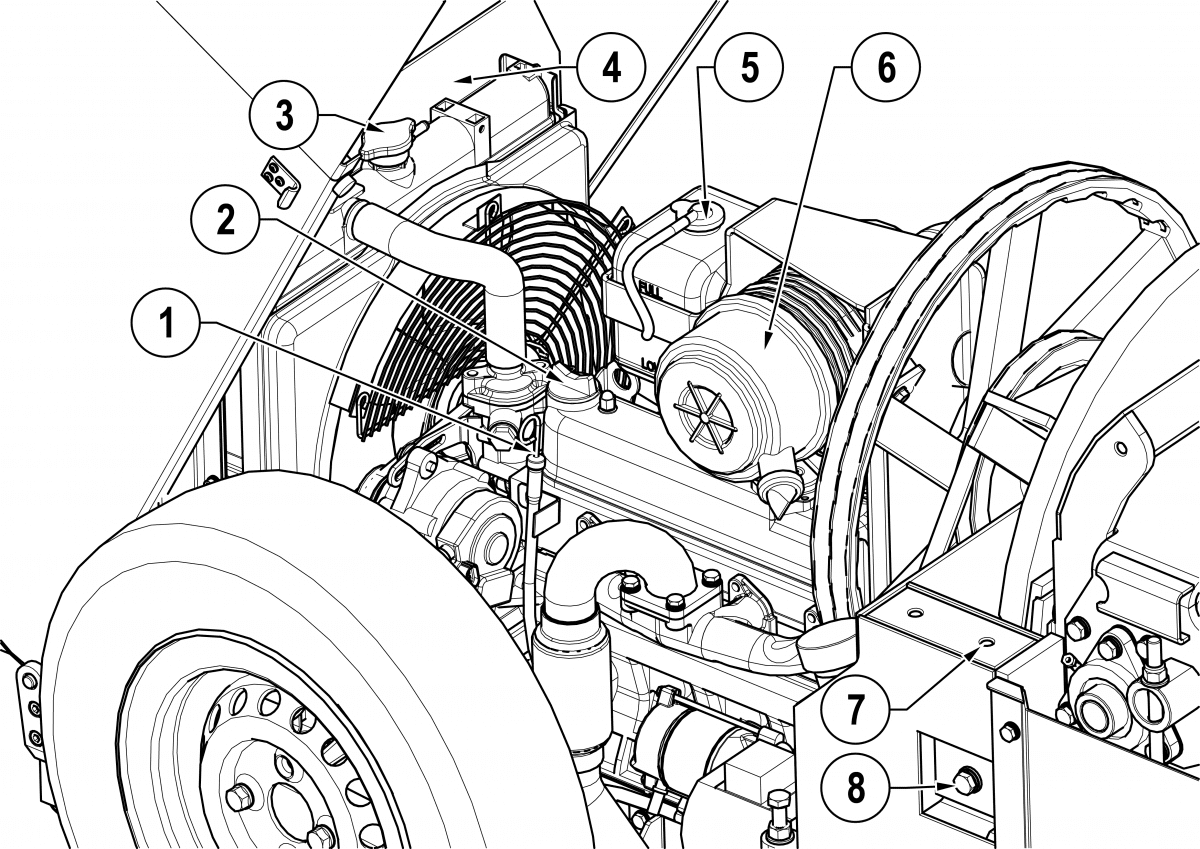

Mechanical Engineering

Mechanical engineering expertise is applied to help your business prosper by designing innovative, efficient products. This covers all aspects that turn a product idea into reality such as design for manufacture/use, mechanisms, plastic injection mouldings, die castings, machined parts, sheet metal, fabrications etc.

Find out more

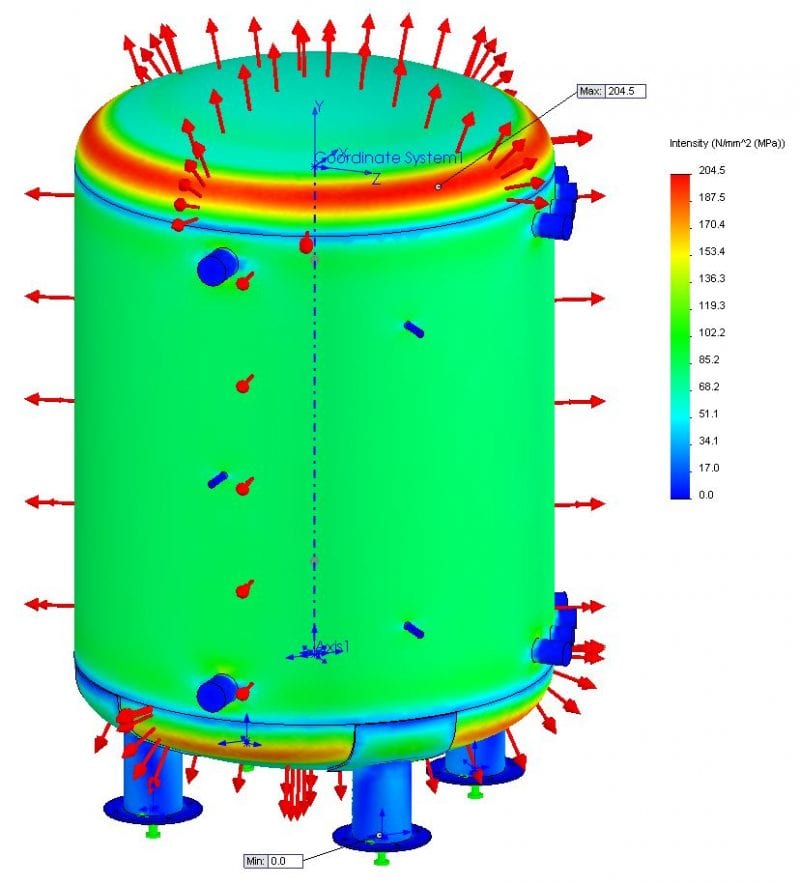

3D CAD Design & Stress Analysis

Analysis is provided as a service on its own or as part of the design process. 3D computer models used for this aid development and analysis at the very early stages in a project as concepts can quickly be put together, iterate many scenarios in a design study and review them for swift development.

Find out more

Product Design

First impressions speak volumes about a product based on its aesthetics. This is why we take great care in applying our engineering product design skill to develop the industrial design aspects of our customers’ products. It is where disciplines such as art, science, engineering and many others come together. Products have to be well engineered on the inside, look great on the outside, be ergonomically sound and easy to use.

We offer a full engineering design service for companies throughout Hampshire, Sussex, Berkshire, Dorset & UK wide.

Find out more

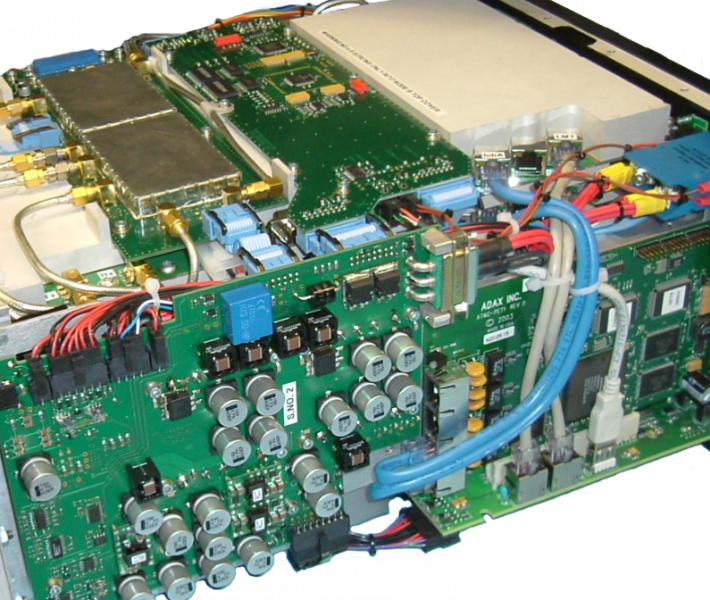

Electronics & Software Design

Specialising in:

Radio Frequency (RF) Electronics

Digital & Analogue Electronics

Software Design & Development

3D Printing & Prototyping

Contact us for your 3D printing, 3D scanning and prototyping needs. We can provide most of the 3D printing processes currently available (SLA, SLS, DMLS, FDM) complemented by vacuum casting, CNC machining, conventional model making etc. in a way that is appropriate for each project or stage of product development.

Find out more

Manufacturing

Suppliers are engaged as early as possible during a project for mutual benefit, to aid understanding and to address design and manufacturing issues at a point when changes are easy and cost minimal. By working in this way, manufacturing queries are dealt with swiftly as the communication paths have been established early on.

Find out moreWhat Our Customers Say

I would be very happy to employ Abraham Associates Ltd again in a similar mechanical design capacity in the event of us becoming involved with large scale mechanical design work in a future project.

Get in touch

Give us a call or send us a message to find out more about our services or to discuss your project.

Get in touch