CCTV Camera

Design summary

Design summary

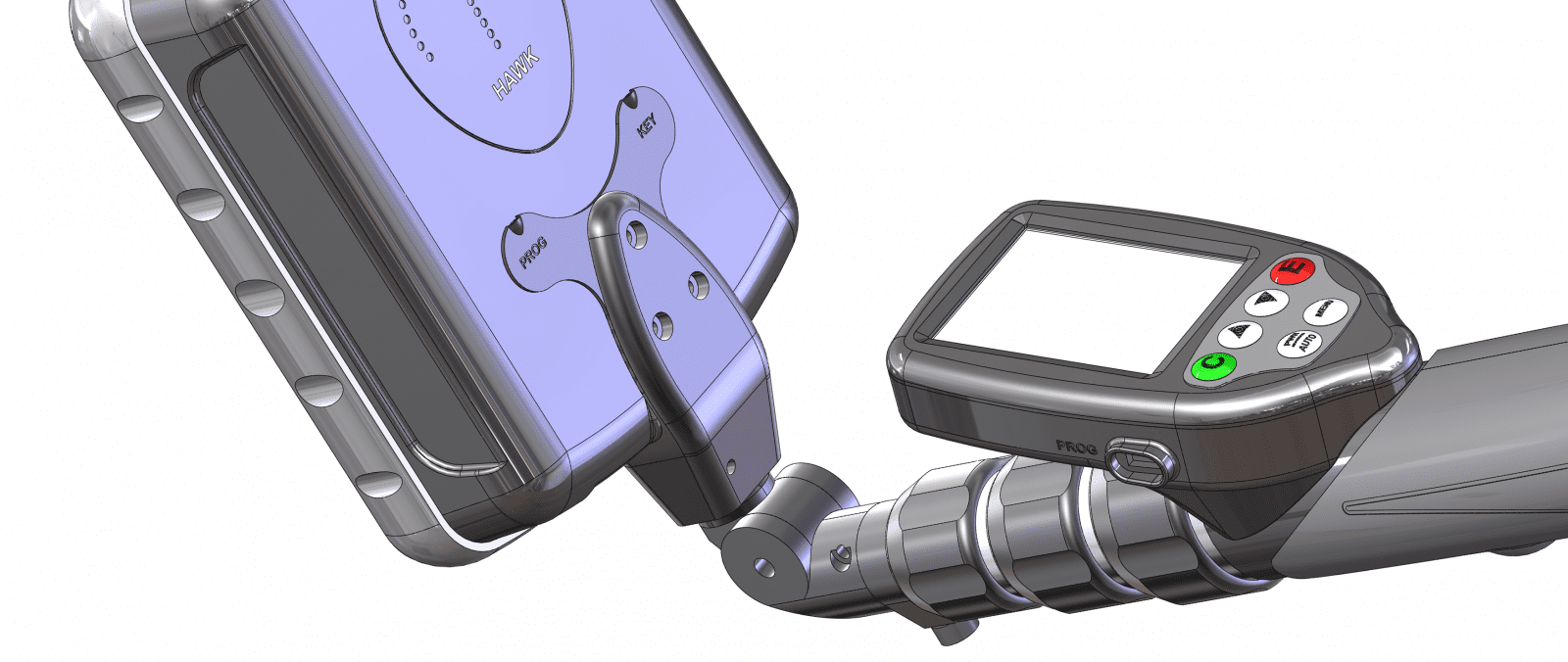

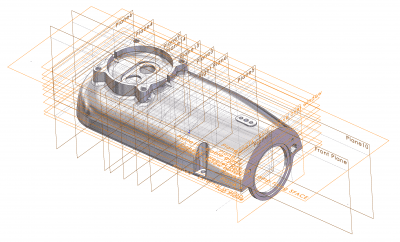

A new generation high quality rugged CCTV pan, tilt and zoom (PTZ) camera was developed for an existing customer as the successor to a similar camera previously designed for them. This novel rugged and compact CCTV camera incorporating Internet Protocol (IP), High definition (HD) camera, high power white and Infra Red (IR) LEDs for night vision exploited a niche within the CCTV market. This concept created a camera platform for current and future camera technology in an aesthetic package that is easy and quick to install. Mounting can be in pendant (hanging down) or pedestal (on top of a pole) orientations. Operation in these orientations is controlled in software and setup on installation. One product efficiently serves both orientations with the minimum of additional components.

Engineering design

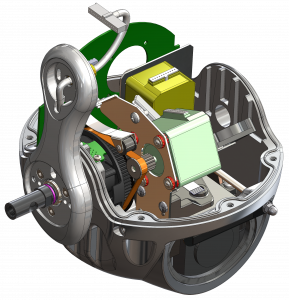

Design for assembly, manufacture and installation were rigorously pursued along with clean aesthetic lines. The whole product was extensively prototyped with 3D printing and tested prior to tooling. This enabled all tooling to proceed to production with no modification. Manufacture was an international affair between the UK, Europe and China. Processes used were quite diverse and involved sintered metal drive components, complex plastic injection mouldings, pressure diecastings, sheetmetal and machined components.

A lot of development went into the camera mounting interface. This was critical as it had to be quick and easy to install/remove at height and yet be very robust and secure to avoid the camera from falling and causing injury or damage. It also had to work in both orientations and with a complete mounting range system.

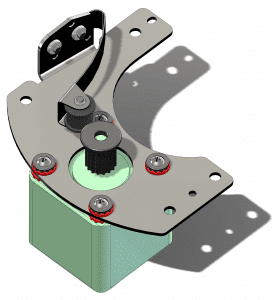

As the camera pans (rotates) and tilts, there were a lot of dynamic considerations and design problems to solve. The drive design had to accommodate the system dynamic movement and inertia. All this was designed well in advance of any physical model by using the 3D CAD mass properties data. Within an already tight enclosure, a design was developed that tilted and paned along with all the electrical connections and electronics. The drive train on this type of camera often suffer from problems due to temperature variation. This was avoided by careful design, lateral thought and proof testing.

As the camera pans (rotates) and tilts, there were a lot of dynamic considerations and design problems to solve. The drive design had to accommodate the system dynamic movement and inertia. All this was designed well in advance of any physical model by using the 3D CAD mass properties data. Within an already tight enclosure, a design was developed that tilted and paned along with all the electrical connections and electronics. The drive train on this type of camera often suffer from problems due to temperature variation. This was avoided by careful design, lateral thought and proof testing.

Thermal design

Thermal management came into incorporating the high power IR LEDs. They had to be kept cool enough for use around the world and not affect the internal electronics. Novel solutions were found for these problems that were simple and cost effective.

Product variants

Several camera variants were also designed creating a camera system. This was extended to include a mounting system of brackets including swan neck and pendant mounts to cover all normal camera locations.

Design support

As with the previous camera, product and engineering support was provided throughout the product life cycle. With a product like this, there are always component supply issues, obsolescence, continuous improvement and manufacturing quality control to maintain.

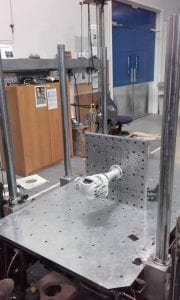

Testing

Testing was conducted at an approved test house or Notified Body. Images below show vibration testing to defined standards and directives. Destructive drop testing was to establish failure modes and ultimate dynamic loads.

CCTV camera vibration testing

CCTV camera destructive drop test. Took 363g at 5ms to fail

CCTV camera destructive drop test

Our Services

Find out moreFind out more about the wide rage of services offered by Abraham Associates and how they can help you with your next project.

Get in touch

Give us a call or send us a message to find out more about our services or to discuss your project.

Get in touch