Lorry scanning detector array

Product overview

Product overview

This detection system works by showing the presence of people hiding in vehicles as they are driven through it. The resultant image scan is similar to an airport X-ray scanner where colour or black and white images are presented to an operator. Use is aimed at ports and other sites where security needs to be maintained. As vehicles are kept moving at normal speed, there is no disruption.

A tight schedule

A tight schedule

An aggressive development and delivery schedule was imposed and met for this large and complex project. Two systems were required for Siemens, one fully operational within three months.

Design

We were engaged to design the system mechanics, structure and alignment jigs. Work started with careful requirement and specification acquisition. A thorough design study developed concepts to satisfy the specification and meet the delivery deadline. Suppliers were identified for all deliverable aspects and involved in early development to also help ensure the delivery could be met.

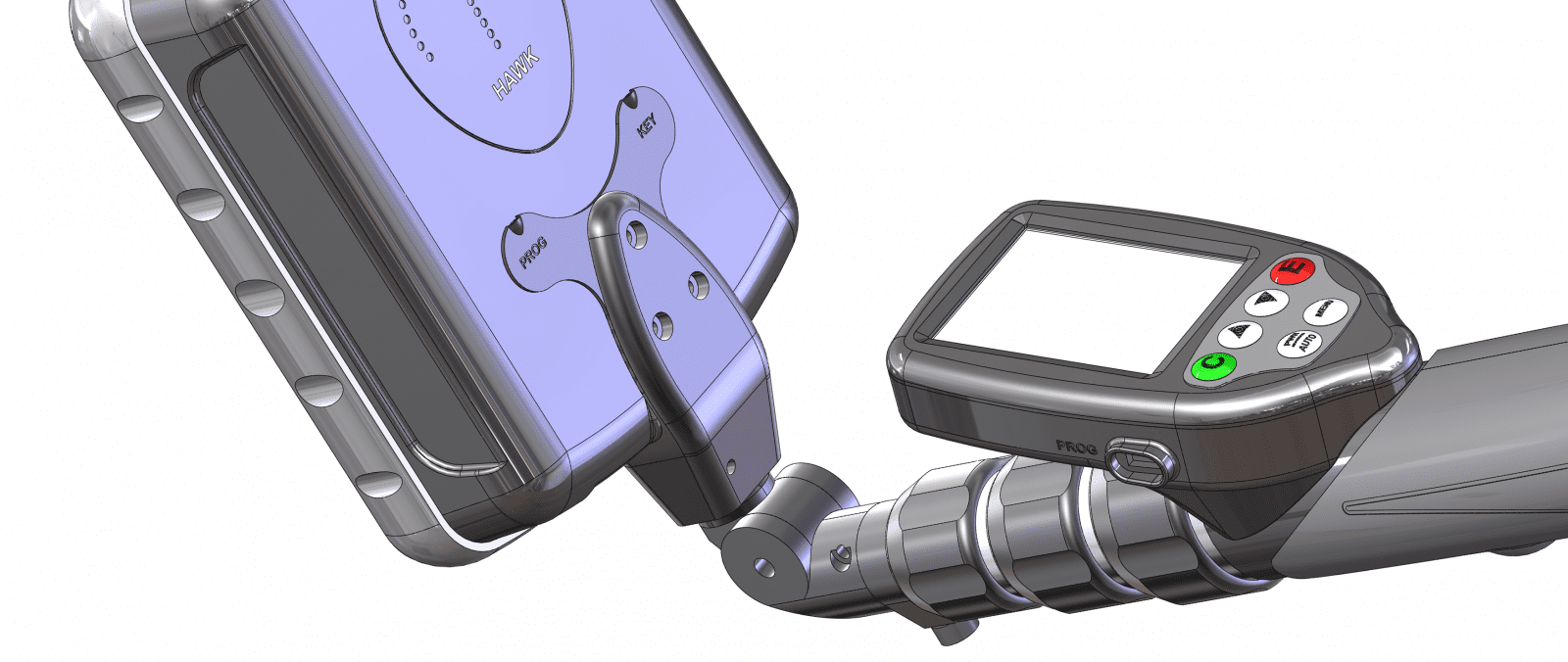

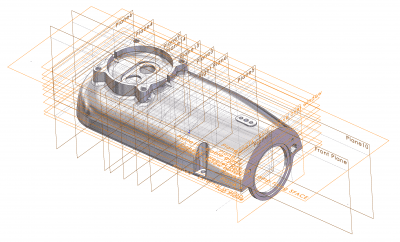

So that the system could be moved to different sites, a modular design was used with each element able to be transported by a standard lorry. This still created some large module structures that had to be accurately set-up. A bank of large detector arrays each over 5 metres high and weighing over a tonne, when assembled, had to be level with each other and ensure the detectors inside were aligned to within ± 0.5° in the vertical and horizontal planes. A simple but effective registration system and procedure was designed for the detector modules that could be assembled with a flat bed truck and hydraulic robotic arm such as a Palfinger. Detector design was more challenging. The heavy box section structure although very rigid, could not be manufactured to the tolerances required. The solution came in the form of two structures, one fitted inside the other. The internal structure provided the precision required and was set-up within the external structure with laser leveling equipment.

So that the system could be moved to different sites, a modular design was used with each element able to be transported by a standard lorry. This still created some large module structures that had to be accurately set-up. A bank of large detector arrays each over 5 metres high and weighing over a tonne, when assembled, had to be level with each other and ensure the detectors inside were aligned to within ± 0.5° in the vertical and horizontal planes. A simple but effective registration system and procedure was designed for the detector modules that could be assembled with a flat bed truck and hydraulic robotic arm such as a Palfinger. Detector design was more challenging. The heavy box section structure although very rigid, could not be manufactured to the tolerances required. The solution came in the form of two structures, one fitted inside the other. The internal structure provided the precision required and was set-up within the external structure with laser leveling equipment.

Detector alignment required a special alignment jig and mount which was designed and set-up to process the many detectors. Two digital protractors were incorporated with manual manipulator mechanisms on each axis. Once set, the detector mount was permanently locked.

Detector alignment required a special alignment jig and mount which was designed and set-up to process the many detectors. Two digital protractors were incorporated with manual manipulator mechanisms on each axis. Once set, the detector mount was permanently locked.

The complete system structure formed a gantry where a lorry could be driven through and scanned. Size of the whole system was 11 metres x 15.5 metres and over 5 metres high.

Delivery

Project completion was on time, within budget and successfully tested.

Our Services

Find out moreFind out more about the wide rage of services offered by Abraham Associates and how they can help you with your next project.

Get in touch

Give us a call or send us a message to find out more about our services or to discuss your project.

Get in touch