Servowriter Positioner

This is very specialised high precision equipment for the computer hard disk manufacturing industry. Servowriters are used in the disk drive production process to write digitally generated magnetic reference patterns on the disks’ surface at very high speed. These reference patterns are used to precisely locate the magnetic read/write heads in the normal operation of a disk drive.

This is very specialised high precision equipment for the computer hard disk manufacturing industry. Servowriters are used in the disk drive production process to write digitally generated magnetic reference patterns on the disks’ surface at very high speed. These reference patterns are used to precisely locate the magnetic read/write heads in the normal operation of a disk drive.

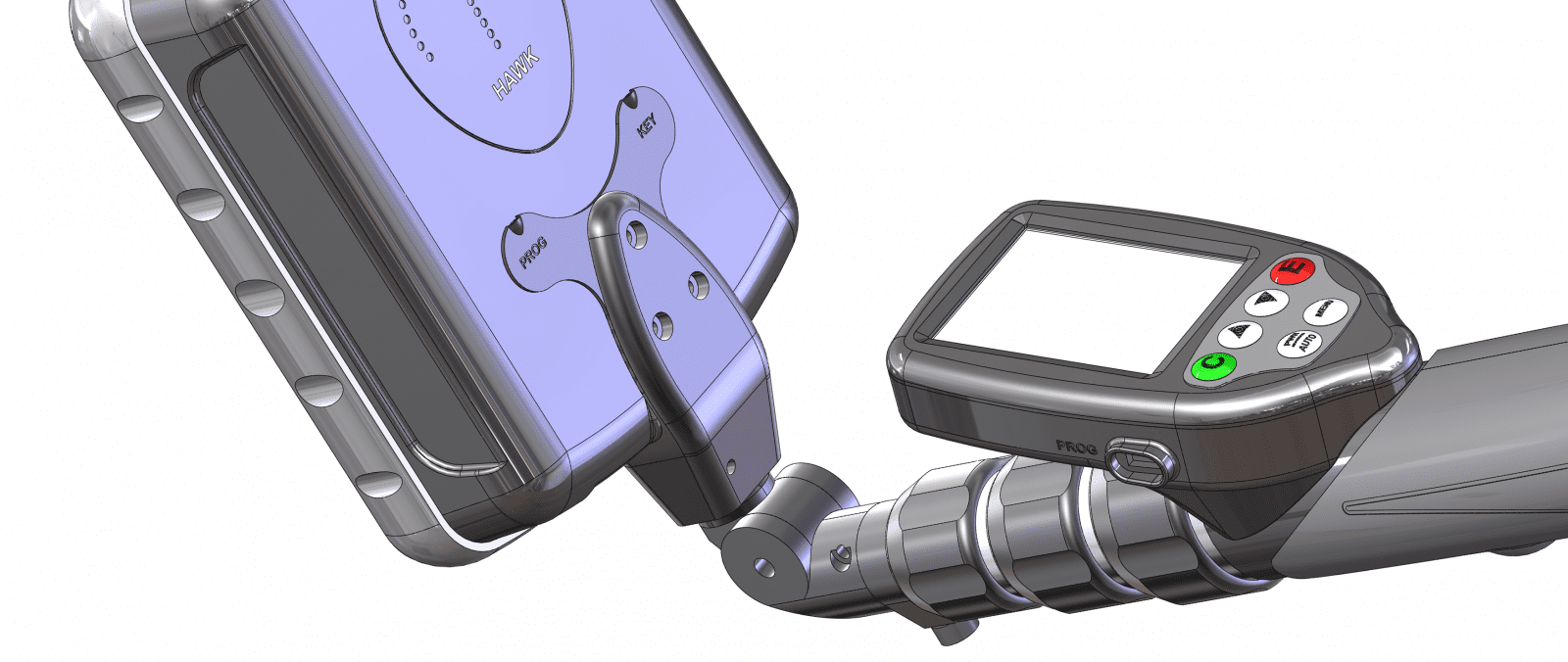

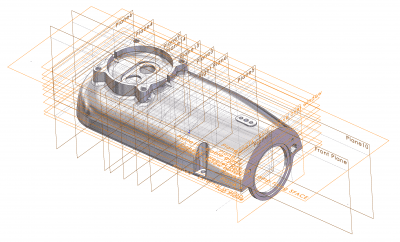

The positioner is part of a servowriter used in the last stages of hard disk assembly to write the data, servo and clock tracks on the disk platens to a very high degree of accuracy and cleanliness. This is carried out in a cleanroom 100 environment as the disk access holes are uncovered during this process. Servowriters are used by all hard disk manufacturers such as Seagate, IBM, Western Digital, Fujitsu etc. At the time of design, common disk track pitch was 1.27mm (micro metres 10-6m). Each track consisted of 4 servo tracks plus a guaranteed space between all tracks and servo tracks. To achieve this, the positioner was designed to give an accuracy of ± 0.25nm (nano metres 10-9m). The positioner’s function is to push the hard disk actuator across the disk surface to create the disk tracks via a “push pin”. Stiffness and balance were also great problems to overcome. For contact positioning, a synthetic sapphire pin was used as this has a high modulus (stiff) and is electrically isolating to help prevent Electro-Static Discharge (ESD). For balance, adjustment weights of tungsten carbide were designed in due to their ease of supply and high density, this minimised size. Rotational power was derived from a custom voice coil motor. The formed precision wound coils and rare earth Nd B Fe (Neodymium Boron Iron) magnets were also custom designed for this product. Bearings were also a challenge. High precision bearings were setup in a pre-loaded configuration to eliminate any clearance. Special grease was also used for the partial rotary stroke operation as ordinary lubrication would fail. A high precision rotary encoder was fitted to the positioner by precision doweling. A corresponding Schott Zerodure chrome on glass scale was optically aligned and set with a bonding process. A special procedure was created and developed for this assembly. All materials and components had to be designed and checked for cleanroom 100 compliance.

The positioner could also be used in a non-contact configuration with a second servo control for servowriting hard disks. A special null sensor was used in place of the push pin and a small machined semi-circular feature had to be added to the hard disk actuator. The main advantage being the positioner was not disturbed by the hard disk actuator and there was much less risk of disk damage.

The positioner was designed for Xyratex (formerly IBM).

Our Services

Find out moreFind out more about the wide rage of services offered by Abraham Associates and how they can help you with your next project.

Get in touch

Give us a call or send us a message to find out more about our services or to discuss your project.

Get in touch